Design Features

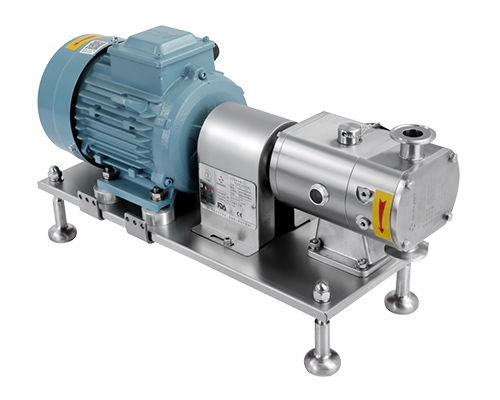

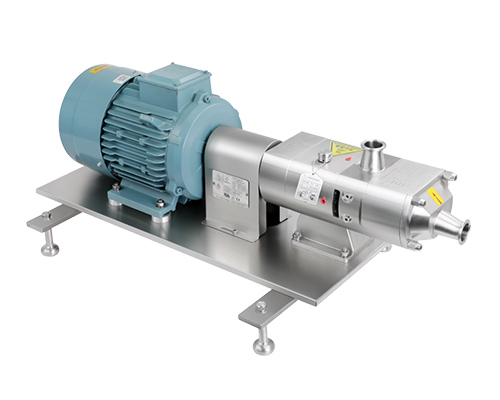

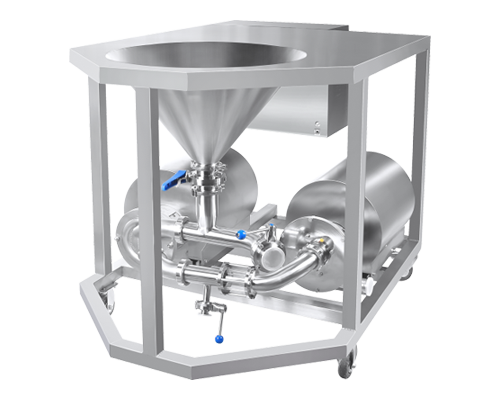

Rotor pump with gearbox, there are three designs:

1) mechanical stepless gearbox, the configuration can adjust speed by hand wheel according to actual requirement of working condition.

2) Frequency gearbox, the configuration can adjust speed through the frequency converter.

3) fixed output ratio gearbox, this configuration is a certain speed and can not be adjusted.

A variety of motor options:

1) Wide voltage efficiency motors IEC EN IE2 efficiency rating (equivalent to China two energy efficiency), PTC thermistor.

2) explosion - proof motor

3) inverter motor

Voltage: AC 220V, 380V, 460V, 690V. 50HZ, 60HZ

◆ Maximum flow: 90m3 / H

◆ Maximum pressure: 20bar

◆ Maximum temperature: 150 ℃

◆ Maximum speed: 750 rpm

◆ Material: ASTM 316L, 1.4404

◆ Inside surface: Ra0.8μm

◆ Certificate: 3-A-02-11NO.1579; CE-MD / 06-42; FDA.177.2600

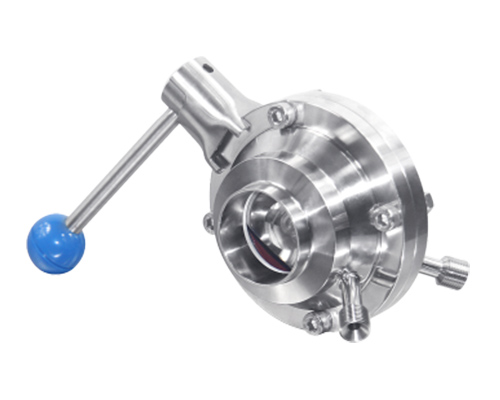

◆ Inlet/outlet: 1) Horizontal TUL; 2) Vertical TUR

◆ Butterfly rotor (standard), Tri-clover rotor, Two leaf rotor, Single leaf rotor

◆ Mechanical seal: Single end mechanical seal (standard) double-end mechanical seal (option) Material SIC / SIC, TC / TC

◆ Suitable for CIP cleaning and SIP sterilization