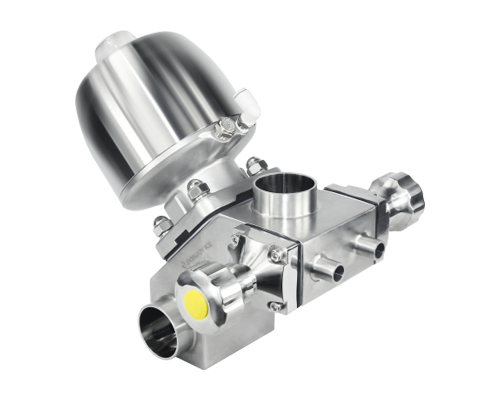

Multi port Diaphragm Valve M-62A

2 control valves, 6 ports

Dead zone = ≤ 1D

Size: 1"-2", DN25-DN50

Material: 316L/1.4404,1.4435 NB2 Fe<0.5%

Temperature: -20℃ +150℃

Pressure: 10bar

Inner Surface Treatment: Ra0.4μm, Mechanical polishing, Electro polishing

Diaphragm: Double diaphragm: EPDM+PTFE; Single diaphragm: EPDM, FPM, Silicon

Operations: Manual/Pneumatic

Control: configurable, 1) Control Unit C-TOP, 2) positioner IL-TOP, 3) mechanical valve regulator, 4) Position Sensor