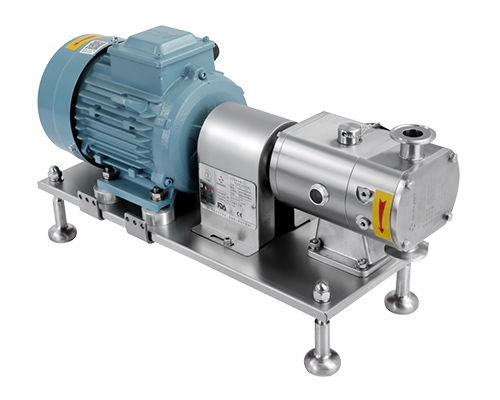

◆The pump is a positive displacement lobe rotor pump designed according to USA 3A standard.

◆The equipment is processed with USA 3A to a very strict hygienic requirement.

◆The pump is suitable for transfering viscous high and low-viscous media in the food-processing,cosmetics and pharmaceutical industries.

◆ Maximum flow: 90m3 / H

◆ Maximum pressure: 20bar

◆ Maximum temperature: 150 ℃

◆ Maximum speed: 750 rpm

◆ Material: ASTM 316L, 1.4404

◆ Inside surface: Ra0.8μm

◆ Certificate: 3-A-02-11NO.1579; CE-MD / 06-42; FDA.177.2600

◆ Horizontal TUL

◆ Vertical TUR

◆ Butterfly rotor (standard)

◆ Mechanical seal: Single mechanical seal (standard) double mechanical seal (option) Material SIC / SIC, TC / TC

◆ Suitable for CIP cleaning and SIP sterilization