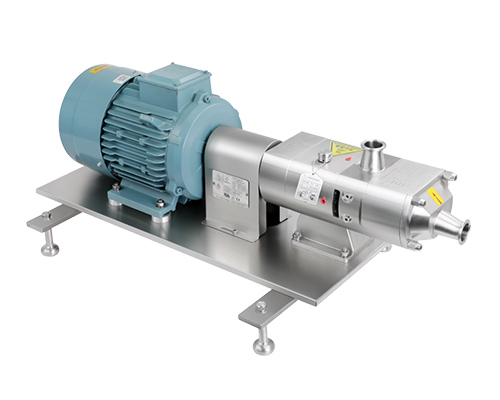

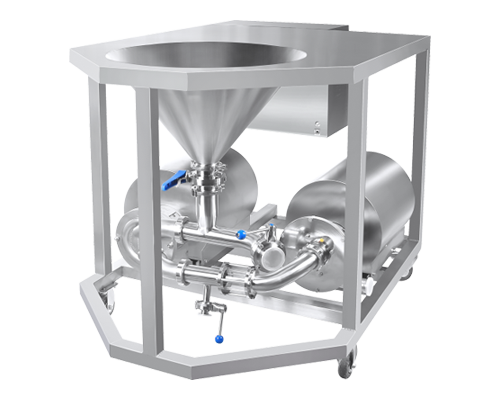

PMZX series is a multifunctional material-liquid mixing pump with functions of mixing, shearing, emulsifying, homogenizing, differentiating, refining, crushing and material quality improvement. Compare with traditional production process, this pump is simpler, more convenient and economical, it can improve the production efficiency & improves the quality of the materials to be treated. Mainly used in food, beverages, dairy products, additives, personal care, biopharmaceuticals, thickeners, industrial applications.

The maximum processing capacity of powder: 9000KG/h

Maximum processing of thickeners: 3000KG/h (depending on material viscosity and concentration)

Maximum temperature: 130 ° C

Material: 304 /316L, 1.4301/1.4404, ASME BPE 316L, 1.4435 BN2 Fe≤0.5%

Surface treatment: ≤ Ra0.8μm, ≤ Ra0.6μm, ≤ Ra0.4μm

Machine seal: single machine seal and double machine seal

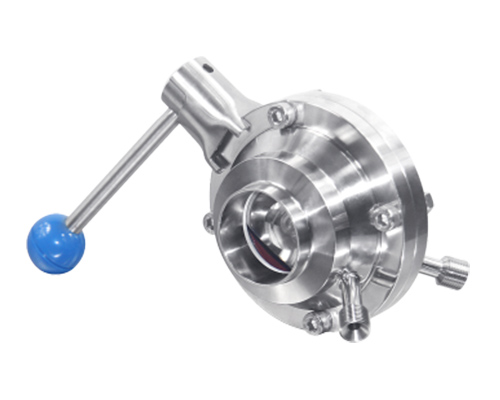

Inlet/outlet connections: Thread, clamp, flange, sterile flange

Certification: 3-A-02-10 (N.O.1579); MD/06/42-EC (N.O.70521616101-00); FDA 177.2600; USP CLASS-II; EG/VO1935/2004;