Pneumatic straight ball valve, both manually and automatically operated valve are mainly used in processing beverages, wine, oil refining, cosmetics and chemical industries.

Thermal insulation ball valve, the valve housing is designed with a jacket, in order to achieve optimum heat transfer. It can protect the easy solidification sensitive medium from solidation, such as chocolate, margarine or similar media.

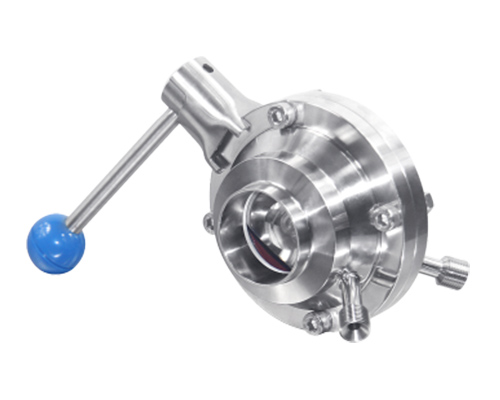

● Size:1"-4",DN25-DN100

●Temperature:-20℃ - 120℃

●Pressure:10-bar

●Material:AISI 304 316L

●Gaskets:PTFE FDA 177.1550

●No matter what kind of liquid flow is, the handle can be mounted on the side of the valve body

●Whatever the connection is, it does not change the total length of the valve

●Connection : Clamp, weld, thread,flange,DIN、SMS、RJT、FIL

●Material contact partsAISI,304/316L

●Other parts AISI 304

●Certificate:PED,97/23EC